Get some feeler gauges that are separate, each with their own handle. That way you can put the gauge in place and just leave it there. Then one hand applies pressure to the eccentric and the other hand tightens the nut.

There’s a DIY on my website that is written for the complete newby (by a complete newby) and is therefore 2X as long as necessary. Here’s my data point.

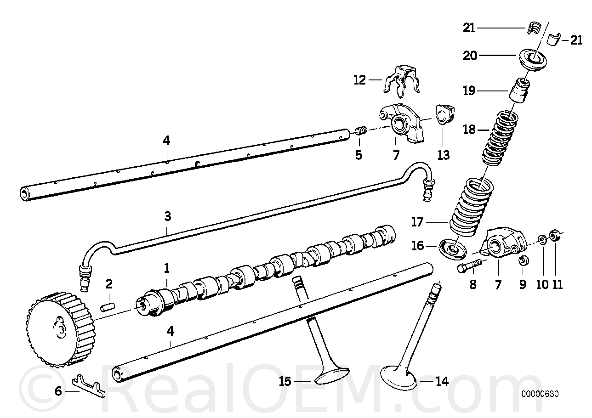

Center the lobes on the opposing cylinder (1-6, 2-5, 3-4).

Tap the rockers to ensure the valves are seated.

Stick the gauge in there. There’s is a technique to this that takes a little practice. It’s easy to get the feeler gauge hung up on the top of the valve stem and cause confustion. If rocker gap feels loose or tight, put in a feeler .002 thicker or thinner to confirm that it needs adjusting. If so , loosen the nut.

Push on the eccentric with a nail or BMW tool and move the gauge around. Adjust your pressure on the nail until the feeler gauge seems able to move around with a little resistance.

Let go of feeler and tighten nut down a little. Since you’ve let go of the feeler this this is a two handed, not 3 handed job.

Wiggle feeler and confirm that resistance didn’t magically change when you tightened the nut down.

Tighten the nut down the rest of the way. Confirm feeler gauge can still move with some resistance. Then grab the .002" thicker gauge and confirm that the rocker isn’t playing you for a patsy.