Couple questions as a begin rebuilding the head I pulled off a cheap spare long block I’d bought.

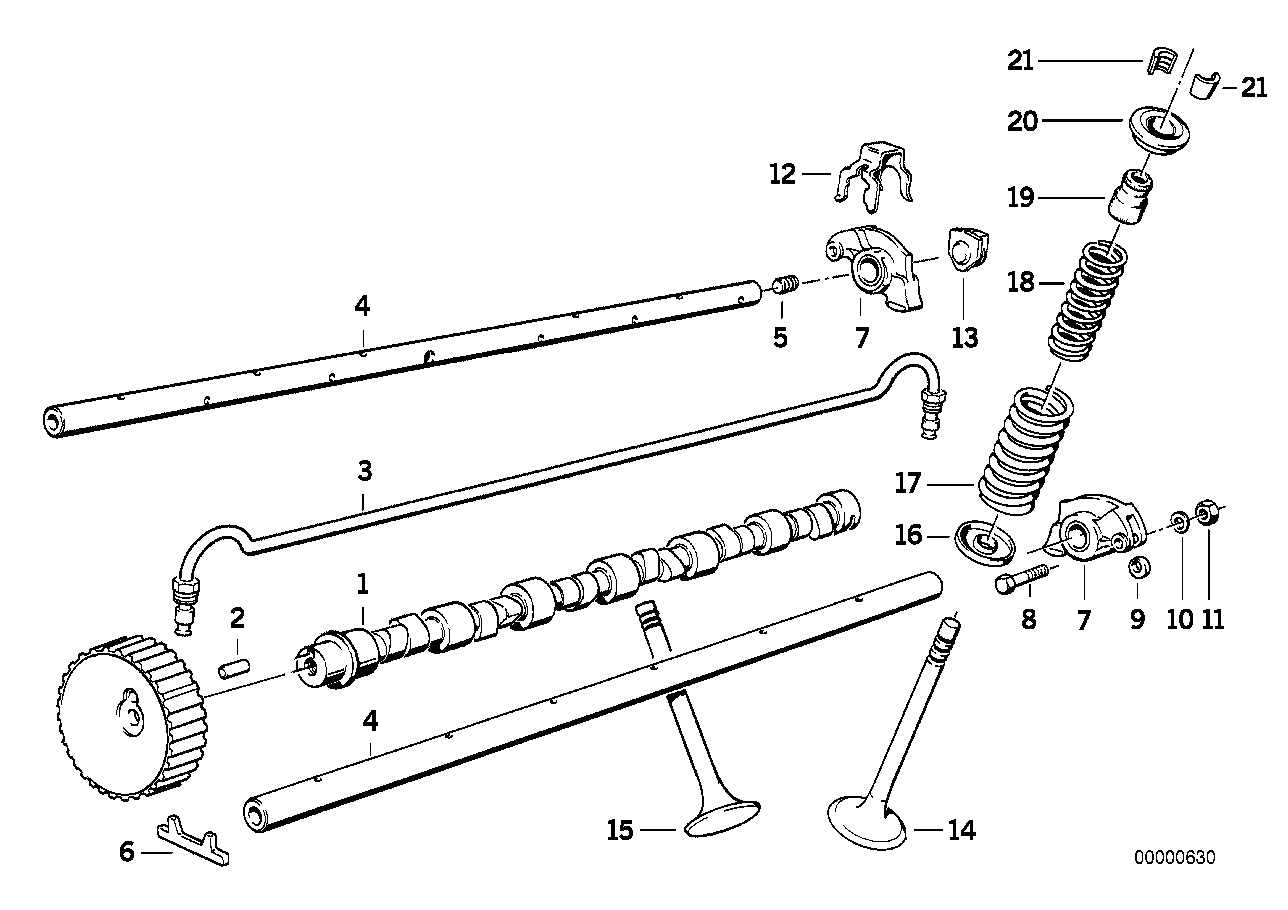

- I’m mid-rocker shaft removal. All the tension is off the rocker arms, but it’s still taking some serious tapping to get the thing to budge (and it certainly won’t slide out by hand). I’ve got it half way through and don’t have a drift long enough to tap any more.

The engine was sitting around without a valve cover for several months. I’m curious if this could cause the difficulty in removing the shafts or if I’m pretty much guaranteed a warped/junk head.

- It seems that the rocker arms only contact the mid-90% of the cam lobes. Shouldn’t it be easy to tell how worn the cam is just by how much of a dip there is between the middle and the 2-3mm edges? The cam I’m looking at looks fairly flat, though I haven’t pulled it to measure yet.

Thanks for any feedback,

Som