So I don’t know where the Miller MAF investigation went, but I recognize that the original AFM isn’t extremely reliable. That being said, I don’t support a wholesale change that requires the entire field to upgrade. Giving it some thought, it appears to be possible to retrofit stock AFMs to behave identically and have a near infinite life. How is this possible you ask? Simple. The proposed solution would be to use an absolute encoder to read position, then convert it to a value that the stock engine controller could read. The output could be exactly identical to a stock AFM, eliminating any need for chips or other upgrades. It’s totally reverse compatible with the original AFMs so nobody feels that they’re at a disadvantage.

So what’s the installation look like? It’d require an external 12V supply to power the added electronics. Other than that it’d be a drop in replacement. I estimate the cost to convert a stock AFM would be around $250-300 and it’d have a near infinite life. In contrast, my genuine Bosch rebuilt AFM lasted only 5 years. If this is something you’d be interested, let me know. Obviously a rule change would be required, but the

In order to make this happen, I’d appreciate some assistance with the electrical design if anyone has that talent. I can design it myself, but would like someone else to assist and comment on the circuit designs. They’re fairly simple, but I’m not an electrical engineer and I’d like this solution to be very robust.

I have an AFM I plan to crack open this weekend to take some mechanical measurements. Assuming that I can fit the encoder in the case, I’ll start drawing up some schematics in the next few weeks. Given my other commitments I don’t expect this to be ready for testing this year, but am gauging interest before I begin. If there is interest, I’d expect a beta test next year and perhaps we could begin converting in bulk during next year, assuming the rules are changed accordingly.

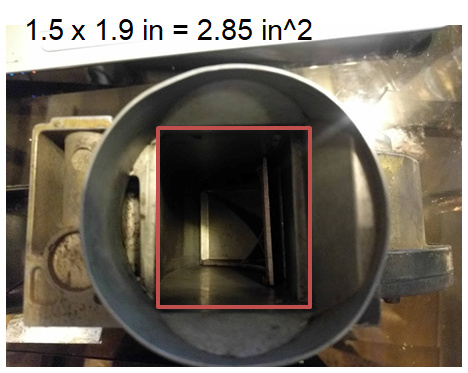

The rectangle is the area that defines the power.

The rectangle is the area that defines the power.