The glorious track debut of New#6 went pretty well. I mean other than it leaking oil like a sieve, and I almost destroyed the engine. Er, again.

Roebling Road, 5Apr12

There were a lot of things to be concerned about. I’d never put any stress on the car at all so I had no idea what it would do. Every orginal part was an unknown. All the parts that had come over from Old#6, like the entire rear end, had taken one heck of a whack and were therefore suspect. I’d been surprised by loose fasteners on the car already, there’d be fasteners that I should have put locktite on, and there’d be the odd fastener that I just failed to tighten. Fasteners just seem to loosen on their own. Because race car.

The oiling and cooling systems couldn’t be trusted because they’d been pulled apart and extensively imagineered. All the gauges and warning lights added possible plumbing failure points, the brakes and suspension had all been redone…the list was just endless. What if the goddamned steering column let go at 120mph?

I did not have any confidence in any single part of the car. Ok, well, the paint I had confidence in. I simply had to head down Roebling’s front straight at 125mph and hope for the best. I swear to god every time I approached the turn 1 braking zone I noted the trees ahead with unease and as my foot moved to the brakes I thought “come on baby, don’t fail me now”.

I was blowing a lot of blue smoke. The engine had done well in carefull compression tests and there was no ring blow-by coming from the rocker arm cover port so I didn’t buy an explanation of leaky rings. I was thinking maybe a bad valve seal. Ever the optimist…“the engine hasn’t hardly been run in 2yrs, lets just drive the piss out of it and maybe it’ll get better”.

After another session I noted that the oil was a little low. After a half dozen more laps of blue smoke I checked the oil again and decided it was no fluke. In fact, one session I was able to see oil pressure dropping in some turns, which was spooky. Not dropping to scary low pressures, but certainly dropping lower than it should have been and doing so because of g-load oil starvation. The oil pump was briefly sucking up air under relatively mild g-load conditions of driving at 8/10ths on 5yr old tires. This was occuring at ~ 1/2qt below “Full”. After a couple iterations of adding oil I was thinking “Damn, that must be one leaky valve seal”.

Other than the blue smoke and losing oil, the car seemed to be doing ok. After careful study of the oil traces I decided that the oil had to be coming out of intake side of the rocker arm cover. That was a darn odd place to lose so much oil, but that didn’t prevent an “Ah hah”. I tightened the already tight rocker arm cover down a bit more and headed back out with renewed optimism.

By lunch I’d gone thru the 1.5qts of oil that I’d brought and, much to my chagrin, had to buy some gas station 20W50 rotgut.

The oil loss continued. The left side of the engine was soaked. I wasn’t doing much in the way of laps because of concern about putting oil on the track. I’d wipe things down a bit so I could see “new” oil, do 2 hot laps and then come in and try to figure out what the source of the oil leak was.

I wondered if maybe there was a way I could blame the blue smoke on the leaky rocker arm cover. “Maybe the oil was dripping down the left side of the car and getting on the exhaust pipe”, I considered, wanting the leaky valve seal possibility to go away. I pulled the rocker arm cover off and checked it for flatness with a level. There was about 1mm of gap right where the oil was coming out. Again, “ah hah”.

Back home Friday night I took the level up to the attic spares dept and picked the most flat of the 5 spare rocker arm covers, and a good rocker arm cover gasket. Then, in a fit of sunny optimism I pressure washed and painted the rocker arm cover.

At the track Saturday morning I put on my flattest rocker arm cover with some RPV goobage and noted just how awful my paint job turned out. “By god this SOB isn’t going to leak” I thought.

“WTF?” I grumbled looking at the signs of freshly leaked oil. I put even more goobage on the cover. That was followed by some more laps, then premature celebration, then leaking, then head scratching and puzzlement.

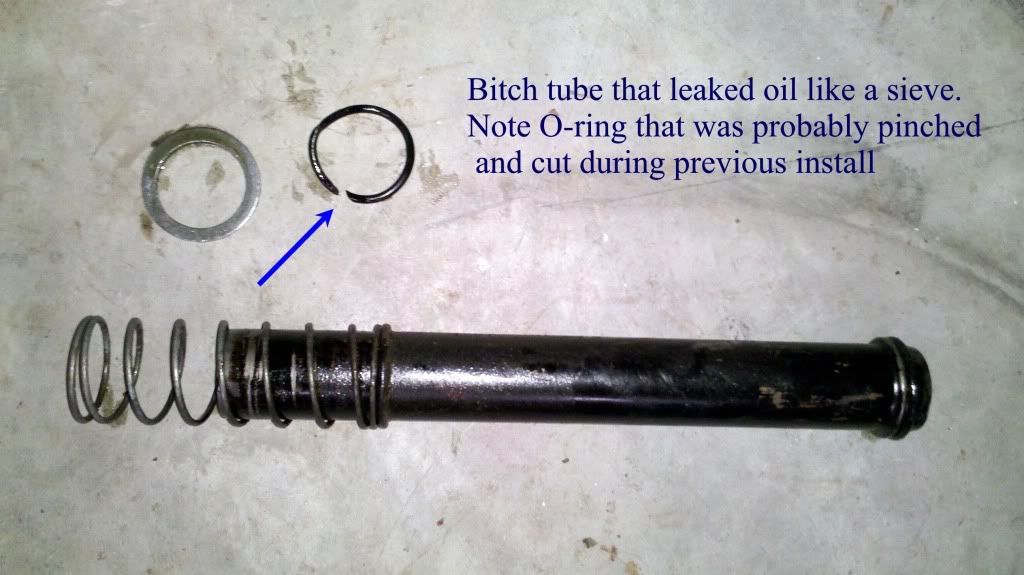

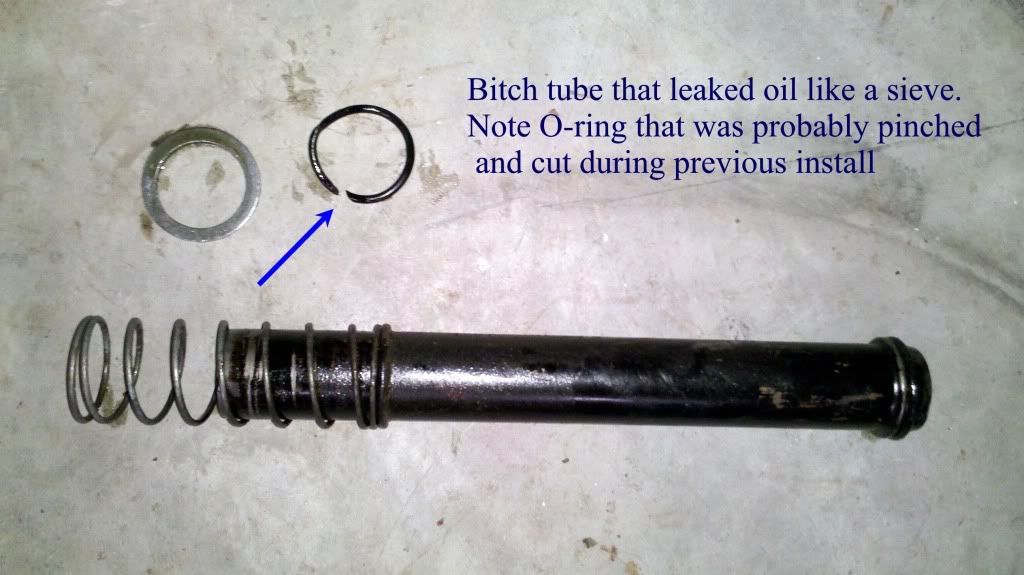

The cause was finally discovered by Jon “Seat-Time” Krolewicz’ dad. He spotted oil burbling out of the base of the Bitch tube, the big oil return/vent tube between block and intake manifold. That ended my day because the intake manifold was going to have to come off to see what was going on with the Bitch tube.

Saturday night I pulled off the intake manifold and the whole coolant system.

Intake manifold off and radiator out for the next day’s work.

With the intake manifold off I did some “porting” of the intake manifold gaskets. For some reason intake manifold gaskets always obscure about a mm of the top half of each intake port. Nothing 30min with a dremel and many test fits can’t take care of tho.

Once the intake manifold was off I pulled out the Bitch tube and the cause of the oil leak was clear.

Seizing the opportunity, when it was time to put the intake manifold back on, I used the one from Old#6 because it had newish injectors.

I also checked some fasteners Saturday night and found, to my shock and dismay, the goddamned Jesus nut, the 304ftlb SOB that holds the lower timing belt pulley to the crankshaft, had come loose. Again. AGAIN for chrissakes. This was the 3rd time it had come loose. I’ve really used up all my luck on this engine. If that bolt had only come a little bit more loose the engine would have been toast.

I had already tried like heck to tighten the Jesus nut as best I could but even with the ebrake on, wheels chocked and trailer straps anchoring the wheels, the best I could do was to torque on the Jesus nut until the clutch slipped. I mean heck the engine is only good for ~150ftlbs of torque, so it’s not surprising that the clutch can’t hold 300ftlbs. I needed to get serious about this so it was time to step back and do some imagineering. The first problem was to hold the crankshaft so it couldn’t turn. The second problem was to apply a calibrated ass-load of torque to the bolt.

In order to get to the Jesus nut and remove the harmonic balancer, the big custom radiator, water pump pulley, and most hoses had to come out. Irksome, but couldn’t be helped.

Sunday morning I fetched a harmonic balancer from the attic spares and welded on a piece of Home Depot angle iron. The idea was that the angle iron would get trapped under a framerail and prevent the harmonic balancer from turning. And if it couldn’t turn, than the crankshaft couldn’t turn.

Next I needed a torque wrench extender. My 1/2" torque wrench is about 14" from socket nub to the center of the handle. So if I wanted 3X as much torque, I needed 3x as much lever arm or 42". So I took the rest of the angle iron and welded a 22mm socket at one end and some misc 1/2" drive socket at the other.

Then I fastened the harmonic balancer crank holder in place, put some blue locktite on the Jesus nut (ok, it’s actually a bolt but I didn’t coin the name), set the torque wrench to 105ftlbs and the Jesus nut happily tightened until the wrench clicked. It’s not very doggone often that my imagineering ideas work on their first try. It was really quite a treat.

Late Sunday night everything was back together.

One more Test and Tune day before the races this weekend.