My IE setup also had the link on the outside of the clamp. There is no way to put in on the inside. I installed it but don’t like how it aligns up. Do we have the wrong part?

Michael O.

My IE setup also had the link on the outside of the clamp. There is no way to put in on the inside. I installed it but don’t like how it aligns up. Do we have the wrong part?

Michael O.

I spoke with Jeff Ireland about this issue and he said they have made the bar clamp both ways; with the pivot in the center and off to one side like I have got. He said they modified the bar to compensate for the geometry change and what is important is what the setup looks like with the car on the ground, not up on jacks. We will see how it works.

4bimmers wrote:

[quote]While Carmine at Carr Industries writes…

"Looks ok. The only thing I notice is the bottom mount for the link needs to be rotated so it matches the geometry of the trailing arm. You can do this by loosening the jam-nut on the sway bar link."

[/quote]

FWIW, this is not possible w/ the IE design. The bottom bracket is too wide to fit in when turned 90deg. One would have to grind off the factory ‘lip’ on the trailing arm tab to accomplish that. Looks like IE designed them to fit only one way - the way 4bimmers has them installed in the pic.

SMD

smdubovsky wrote:

FWIW, this is not possible w/ the IE design. The bottom bracket is too wide to fit in when turned 90deg. One would have to grind off the factory ‘lip’ on the trailing arm tab to accomplish that. Looks like IE designed them to fit only one way - the way 4bimmers has them installed in the pic.

SMD[/quote]

IE bracket is beefier then stock so yes you are right that lip has to be modified , or completely cut-off (if you don’t want to mess with the fit). IE rear links come with reinforcement plates, you can weld those and be fine. Either way make sure that link is installed in proper orientation and not 90 deg off.

I personally tossed out IE reinforcements and made my own (and modified lip to fit)

Igor

To my knowledge, the bottom bracket is fine. The bracket got two tabs that prevent the rotation of the bracket, and the only way to do that is installing the bracket like that.

The headbolts "heads" have to face outwards.

Does anybody have other pics?

I’ll check my Z3 since I got the same swaybars and snap some pics.

The reinforcements can be welded or bolted, mine are going to be welded.

How about the swaybars mounting brackets reinforcements? I got the IE and are pretty easy and look sturdy.

so to be clear. for those of us w/ the clamps that does not allow the link to go in the middle, is the inside the preferable location for the link?

Thanks

TXBDan wrote:

[quote]so to be clear. for those of us w/ the clamps that does not allow the link to go in the middle, is the inside the preferable location for the link?

Thanks[/quote]

I would say yes since it looks like it can only fit that way (i.e. reach the swaybar). I would put the bolt (that goes through the clamp) such that threads that are sticking out point to inside of the car (away from the spring).

I still think that it’s weird setup on IE’s part - almost like they used front link and just put the clap on it for use on the back (or did they just send the wrong parts - I know that some people talked to them but …)

Igor

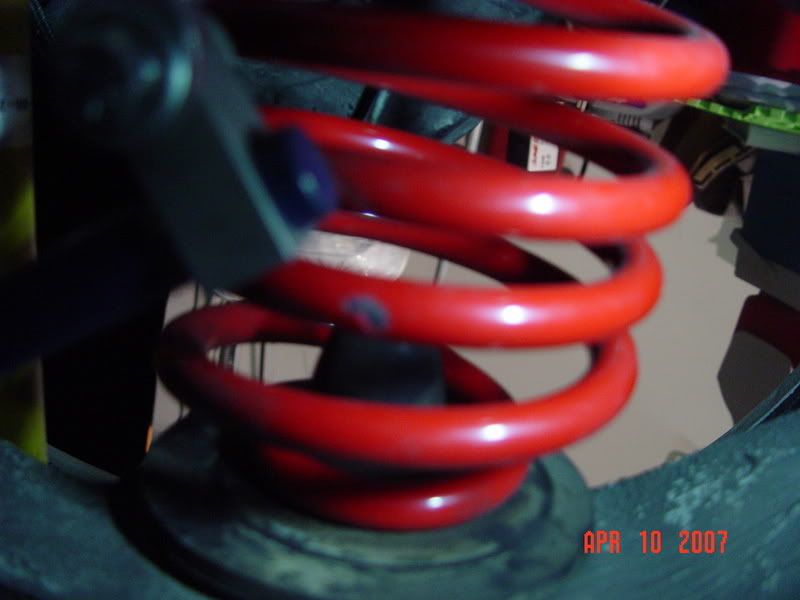

yeh thats the way i ended up as of yesterday. seems to be the best, but not ideal. i tried to the outside and inside and the inside cleared the spring by about 1/4". The outside (with the clamp rotated inward) was quite close.

i checked most of the range of travel and it should be fine, but i’ll email and ask about getting a middle type clamp.

Let me know what you find out about the "middle" clamp design. I actually have designed one that will work but have not been able to get it machined yet.

before you make new links/clamp, you may want to clarify their acceptability …

cheers,

bruce

4bimmers wrote:

TXBDan wrote:

[quote]yeh thats the way i ended up as of yesterday. seems to be the best, but not ideal. i tried to the outside and inside and the inside cleared the spring by about 1/4". The outside (with the clamp rotated inward) was quite close.

i checked most of the range of travel and it should be fine, but i’ll email and ask about getting a middle type clamp.[/quote]

So, you got them this way?

Or this way?

I’d rather have them as the second pic, but with the head of the bolt on the outside, near the springs.

As they are installed, by my pro mechanic, they rub the springs.

I guess my first installation was incorrect

I just don’t like the looks of that link setup compared to mine. In my opinion your link attachment to the outside of the clamp just doesn’t look as secure or stable as having it in the middle of the clamp like mine from Ireland. Maybe it doesn’t make a difference but I would ask (good luck) if they will send you the clamp that will allow the link to attach in the middle. Sorry I can’t post a picture of mine, its getting painted.

screwynewy wrote:

I agree. You know the pic they have posted in the IE website shows the clamp with the link in the middle. I will request that one instead of the outside setting. Meanwhile, I have to deal with it tonight and drive with it this weekend, something else to have in mind.

OK, I had to contact IE because it was driving me crazy.

Directly from them. with the new clamp design, the rod end goes inside (facing differential), and the bolt head on the outside (facing the spring)

Here the rod is in the wrong side, and the headbolt is fine.

Here the rod end is fine, the bolt head has to go on the outside.

Have to work on that tonight. I’ll take pics.

Victor (Beto),

You need to rotate your lower sway bar link mount 90 degrees so that the aurora bearing will pivot front to back. The way you have the link attached will cause it to bind when the suspension is compressed.

Glad you got clarification on the correct installation on the upper clamp.

Ken’s observation is right on the point - I know that if you install it 90 deg from where it is in the pic, it will look as if it doesn’t fit, however it is the correct orientation. It will not fit perfectly because the IE bracket is beefier then stock, hence you will have to grind the lip on the trailing arm. Also don’t forget to put in (weld) reinforcement supplied by IE (triangular bracket with the hole in the middle). Better yet fab up your own or buy one that will triangulate to vertical side of the TA as well.

Igor

You know what’s funny, my mechanic installed them like that to prevent binding. I’m switching mechanics. I’ll rotate them tonight. I already got the tabs welded in top and bottom, you can see them in the pics.

OK, so here is the proper location of the rod end and bolts.

Loaded

Unloaded

yep, youre last sequence of pics look just like mine except for the bottom bracket needing to be turned 90deg.

I ran it on the track last weekend and i didnt encounter any trouble. nothing is binding or rubbing

Igor wrote:

[quote]Ken’s observation is right on the point - I know that if you install it 90 deg from where it is in the pic, it will look as if it doesn’t fit, however it is the correct orientation. It will not fit perfectly because the IE bracket is beefier then stock, hence you will have to grind the lip on the trailing arm. Also don’t forget to put in (weld) reinforcement supplied by IE (triangular bracket with the hole in the middle). Better yet fab up your own or buy one that will triangulate to vertical side of the TA as well.

Igor[/quote]

I tried last night to rotate, and it won’t because of the lip. Isn’t that the purpose of the lip and the tab on the bracket? To prevent rotation of the bracket. Checking with IE again, I didn’t want to grind the lip. I ran two weeks ago, with the former setup, and didn’t have any issues binding.

Igor wrote:

[quote]Ken’s observation is right on the point - I know that if you install it 90 deg from where it is in the pic, it will look as if it doesn’t fit, however it is the correct orientation. It will not fit perfectly because the IE bracket is beefier then stock, hence you will have to grind the lip on the trailing arm. Also don’t forget to put in (weld) reinforcement supplied by IE (triangular bracket with the hole in the middle). Better yet fab up your own or buy one that will triangulate to vertical side of the TA as well.

Igor[/quote]

I tried last night to rotate, and it won’t because of the lip. Isn’t that the purpose of the lip and the tab on the bracket? To prevent rotation of the bracket. Checking with IE again, I didn’t want to grind the lip. I ran two weeks ago, with the former setup, and didn’t have any issues binding.