I had some symptoms at Roebling last month that seemed to be fuel starvation. This car is relatively new to me and I had never had it at Roebling before. The track has fast left and right hand sweepers that stress fuel and oil pump pickups.

I learned a lot along the way about hoses and fittings.

I started with this inexpensive fuel surge tank. Fuel Accumulator – Ireland Engineering | Racing & Performance Parts for BMW & MINI

I bought the big one with 6AN fittings, but the small one with 1/4NPT fittings would have been adequate. If you went with the small surge tank route, I’d adapt 1/4NPT to 6AN and drive on.

Where to put the surge tank. I requested pics of surge tank installs on fb to see what others had done. All the surge tanks were either between the rear shock towers, or in the spare tire well. I didn’t like the spare tire well solution because not only is that a convenient place for ballast, but it’s also part of the car’s rear “crush zone” and I wanted the surge tank more protected.

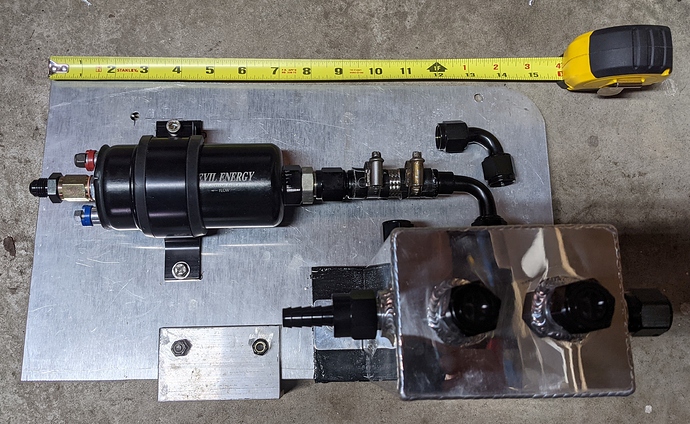

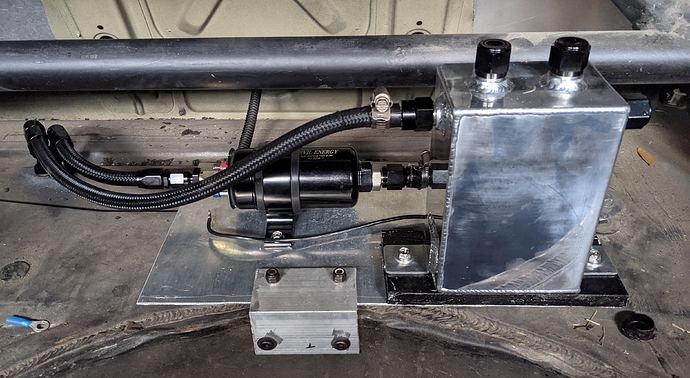

Instead of trying to fasten a bunch of things thru the rear sheetmetal floor, I used a piece of relatively thick AL sheet as the base for it all. The AL sheet is fastened down at 4 points.

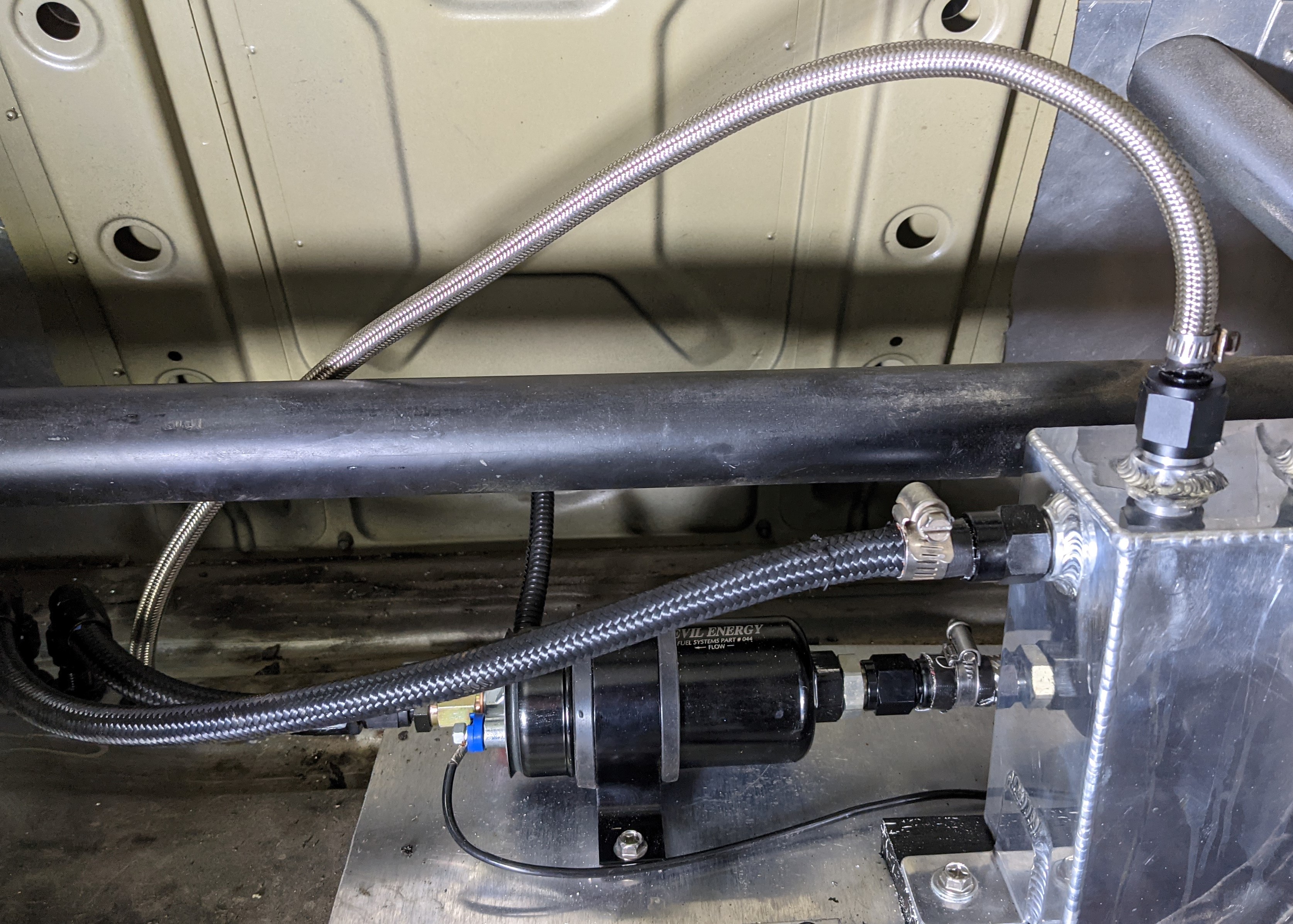

There were some constraints that had to be worked around. I wanted some distance between the surge tank and the horiz bar, I wanted to keep hoses away from where things happen like putting a spare tire in the tire well, and also the spare parts bins live in the trunk between events. Also, as it became clear where the fuel lines were going to penetrate the trunk floor, it was obvious that I needed to keep the hardware kind of distant from those holes so hoses had space to make graceful turns. Finally, I wanted to stay clear of the rear sway bar fastening point.

Hoses and fittings were the tricky part.

–The OEM hoses are 8mm, call it 5/16". Some folks will say that 8mm isn’t 5/16th, but it’s close enough for me.

–The surge tank has 8AN fittings, but 8AN hose is 1/2" dia with is silly big. Buy some 8AN plugs, but don’t buy anything that’s gonna want 1/2" hose.

–My pump came with a 6AN outlet adapter. That’s 3/8" hose which is fine. The pump inlet was 18mm tho and that required a couple different tries at adapting so something more useful. Ultimately I adapted 18mm to 8AN.

–The bulkhead adapters. I went with 6AN. On top I used 6AN fittings and 3/8" hose. That went happily to the pump because it had a 6AN outlet. In order to get the 3/8" hose to fit on the surge tank’s 8AN port, I bought a 8AN to 3/8" barb. That’s important because if I had just bought a 8AN fitting, it would have been too big for the 3/8" hose. Remember, 8AN is 1/2" hose.

–Push Lok fittings. At first, I didn’t understand that these were different then generic hose barbs. I had problems connecting them to hose and almost switched to all barbs. But then I did some reading and realized that Push Lok was better and that it was just a matter of knowing how to fasten them to hoses. I was confused enough about this that I bought an expensive tool to install Push Lok fittings. Only after ordering it did I figure out how to put them on hoses such that no tool was needed. AN Hoses and Fittings Guide — Kanga Motorsports

In the pic above note the 90deg elbow, upper right, that is not connected to anything. One plan that was discarded in the last hours of this effort was that solid AL elbow. I decided that it was a bad idea to rigidly connect the surge tank and pump. The short piece of AL tube would have to deal with it’s two ends vibrating in different ways and that seemed like a lot of unnecessary stress on the AL fitting.

So in order to create a little mechanical isolation between pump and tank, I connected the two with 8AN barb fittings an a short piece of 1/2" SS hose I had laying around. Since they were barb fittings, I put on hose clamps.

Don’t risk a weekend by going cheap buying a POS aux pump. Get one that people are saying nice things about.

Connecting the bulkhead fuel in (6AN) adapter to the surge tank’s 8AN inlet was the one departure from using AN fittings. In order to mate the two I used 3/8th hose, or call it 6AN hose, and used a 8AN to 3/8th barb at the tank. Since it too was a barb fitting, It needed a hose clamp.

Tape on the hose before you cut it helps. The act of cutting makes the braid fray and then it’s hard to put on a a Push-Lok

Tapping fuel lines. This car is a late model and it’s fuel filter has been moved to the engine bay. My first plan had been to tap into the fuel line at the pump. Some folks had success routing the fuel lines above the tank, moving the line towards the center hump, and then pushing the fuel lines rearward so they pop out near the Ebrake pipe. I spent some time trying to make this work, but decided that dropping the tank a bit would be necessary–the hoses were not going to fish thru w/o some more room.

I looked at the minimal clearance between driveshaft and fuel tank and imagined a scenario where in order to win a 1/2" of clearance, I’d have to drop both tank and driveshaft. I was not enthusiastic about that. So I went back to the fuel lines near driver side subframe mount and wargamed various ways I could safely run hoses back to the trunk. There’s a brake line there that looked like it had reasonable clearance with everything, so I resolved to tap the fuel lines by the subframe bushing and then thread 5/16" hose along the brake line.

Has to be 5/16" hose because it’s going to connect to the OEM steel pipes. Has to be plain flexy rubber hose because you can get 5/16" hose on 6AN fittings which was the appealing solution for the bulkhead adapters. . If you try to use 5/16th SS or nylon mesh hose, you’re going to need to do something more complicated at the bulkhead because that hose won’t “swell” enough to fit a 6AN fitting.

To say that a different way, under the car you have to have 5/16" hose to connect to the OEM steel pipes. In the trunk you can have anything you want, but 6AN is a good solution. So it’s at the bulkhead adapter that you’re going to have change 5/16" to something else.

A really nice solution would have been 5/16" SS mesh hose under the car connecte4d to 5/16" 90deg barb 6AN fittings at the bulkhead adapters. But even after buying an assload of fittings as plans came and went, I did not have two 5/16" 90deg barbs in 6AN.

Here’s the 6AN Bulkhead adapters from underneath. That’s 5/16th hose. I took the pic with one hose off for better perspective. That hose remained off when I did some testing with the OEM pump filling the surge tank. I ended up with a quart of gas on the garage floor. Sometimes I wonder how I’ve survived all my stupid mistakes.

Here’s the bulkhead adapters from above. That’s 6AN nylon mesh hose.

A charm of going with 6AN bulkhead adapters is that the holes in the trunk can be relatively modest.

The steel fuel line to the engine took an awkward turn in it’s last couple inches. I didn’t like how that was going to cause my rubber hose to take a sharp bend, so I decided to get rid of the steel line’s awkward turn. Then I pulled out a flare tool and made a little flare at the end to help the hose clamps seal. The pic below shows the steel fuel line cut and the flare tool.

Here’s everything installed. It’s hard to see from this perspective, but there’s a 2" gap between the tank and the horiz bar.

I pulled power for the Aux pump from the OEM pump. I did this because I like how the OEM pump stops if the engine stops. Hopefully that circuit will be up to the demand of running both pumps.

The tank is on a black piece in order to raise the height of the tank by 1/2". This was necessary in order get the tank’s outlet at the same height as the pump’s inlet. The hose between the two is very short so making the two ports coaxial reduces stress.

AN fittings have to be tightened with wrenches. Make darn sure that every single thing is appropriately tight before installing stuff in the car. And if you have choices re. what end of a fitting or hose has to be tightened only after installing in the car, make it the thing that is easy to get to. What you’re trying to avoid is a fitting that isn’t tight enough so it leaks, but it’s a fitting that you can’t easily get a big wrench on.

Separate your bulkhead fittings such that they have at least an inch between them. That will give you room to put a wrench on them in a tight area. Otherwise you’re gonna be cutting wrenches down to make them shorter.

Bulkhead fittings look cool, but they add a lot of complexity. Consider blowing off bulkhead fittings and just make a big hole instead with some kind of big grommet.

AN fittings have to be tightened with wrenches, it’s not like having an easy to get to hose clamp. Make darn sure that every single thing is appropriately tight before installing stuff in the car. And if you have choices re. what end of a fitting or hose has to be tightened only after installing in the car, make it the thing that is easy to get to. What you’re trying to avoid is a fitting that isn’t tight enough so it leaks, but it’s a fitting that you can’t easily get a big wrench on.

Separate your bulkhead fittings such that they have at least an inch between them. That will give you room to put a wrench on them in a tight area. Otherwise you’re gonna be cutting wrenches down to make them shorter.

Bulkhead fittings look cool, but they add a lot of complexity. Consider blowing off bulkhead fittings and just make a big hole instead with some kind of big grommet.

Making a mess is almost unavoidable because you have to fill the surge tank with gas. Otherwise it could end up being a volume of pressurized air, not fuel. I opened a top cap, turned on the OEM fuel pump by shorting the right relay pins, and when fuel started spraying around the trunk, I ran forward and yanked the wire out of the fuel pump relay socket.

Pump mount. https://www.amazon.com/gp/product/B07WCV127B/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1

Pump. https://www.amazon.com/gp/product/B07Y9WW183/ref=ppx_yo_dt_b_asin_title_o00_s00?ie=UTF8&psc=1

5/16th fuel injection hose https://www.amazon.com/gp/product/B06Y273SF8/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1

6AN hose and some fittings. https://www.amazon.com/gp/product/B08H29LPFR/ref=ppx_yo_dt_b_asin_title_o05_s02?ie=UTF8&psc=1

6AN bulkhead fittings. https://www.amazon.com/gp/product/B074XDC1QY/ref=ppx_yo_dt_b_asin_title_o05_s00?ie=UTF8&psc=1