Bottom line. Beefy. Big bearing. Easy undo strut shaft nut. Pricey at ~$450. No advantage in stack height over GC E30 camber plate. Looks to me like a superior design, but I don’t know that it’s worth the extra cost.

Now that we have our new springs, I wanted to check out the other camber plates that are now SpecE30 compatible. That is to say, now that we no longer need to shove down the OEM spring hat, conventional E30 camber plates work for us. We just don’t know much about them. Or at least I don’t anyways.

I talked to Vorshlag about their conventional E30 camber plates. They said they have the lowest stack height (no), the best bearing design (probably so), and are the most durable (could be so).

Stack height. I measured my old camber plates against the Vorshlag camber plates. I talked to Carlos (Condor Speedshop) to make sure that I was measuring the stack height the exact same way he did on his darn useful write-up (The truth about Spec E30 Camber plates. – Condor Speed Shop). This would be a good time to go review that.

<where the hell is everyone else in writing up stuff of lasting value?>

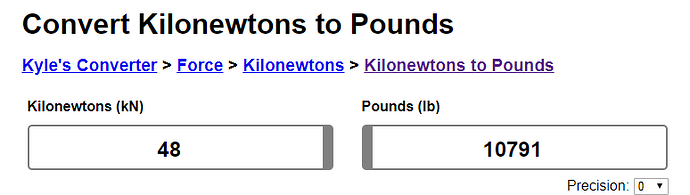

It’s interesting that Carlos found a fairly large difference in camber plate stack height between GC SpecE30 camber plates and GC conventional E30 camber plates. My SpecE30 camber plates were at stack height disadvantage of only 9mm of compared to conventional E30 camber plates. That is about half the 17mm disadvantage that Carlos found. Given our that stack height is less critical now then it used to be because our springs are so much stouter, and noting that the Aussies are not obsessed with lowering their cars, I have to wonder if 9mm is worth $350 to $450. Carlos’ Condor “Conversion” option does hit a nice price point tho.

What I found is a) Vorshlag (conventional E30) camber plates have the same stack height as GC (conventional E30)plates, and b) maybe I don’t have “old school” GC plates like I thought I did.

Below is a pic of the stack height of my camber plates in the new config with the GC “misalighnment spacer”. Stack height is 46mm, which is 6m more bump travel than late model GC SpecE30 camber plates (See Carlo’s doc). This would seem to indicated that my car had more bump travel than your GC camber plate equipped car, and was therefore faster. Too bad it’s driver was not.

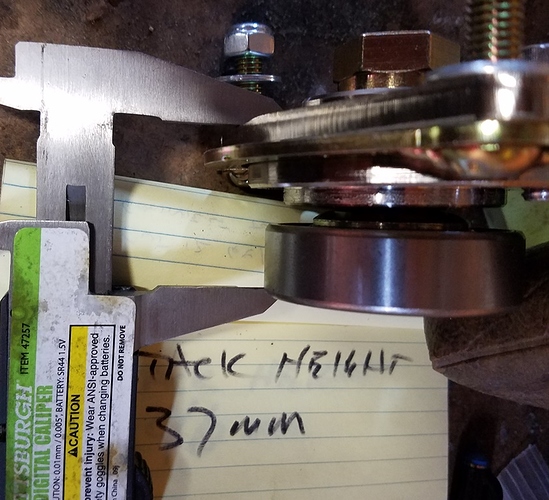

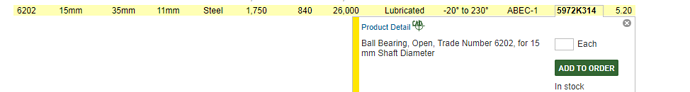

The pic below shows the stack height of the Vorshlag conventional E30 camber plate.At 37mm, Per Carlos’s page, that’s the same as the GC conventional E30 camber plates. Therefore no bumptravel advantage in Vorshlag over GC. Note that when I ordered these from Vorshlag,I had to tell them that I had Bilstein B8’s and mine were 12 x 1.5mm thread. Note that 12x1.25mm apparently also exists.

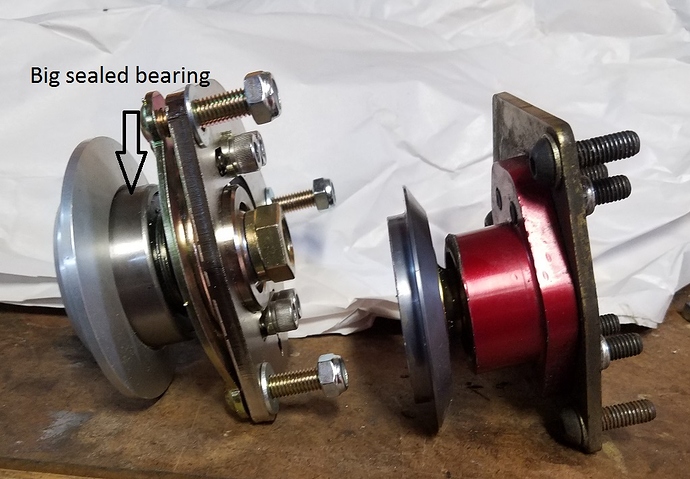

The next pic shows a profile shot of both camber plates, Vorshlag being on the left. My camber plate (right) has the GC top hat. The Vorshlag camber plate has it’s own proprietary top hat. The two won’t mix. From the perspective of rules, you’re ok to use the Vorshlag top hat.

Note on the Vorshlag camber plate the big-ass sealed bearing. That’s the stand-out best feature of the Vorshlag camber plate.

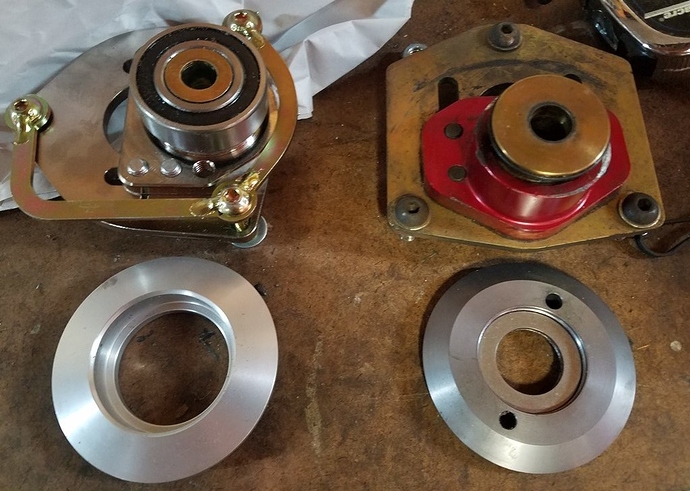

Next pic shows my camber plate, a design very similar to GC, at an angle that shows how the GC “misalignment spacer” fits into the top hat and presses on to the GC washer needle bearings. The GC bearings aren’t “sealed” but there is a rubber ring in the right place to keep out debris. So lets call it “somewhat sealed”.

The next pic shows the Vorshlag camber plate at the same angle. Note the sealed bearing.

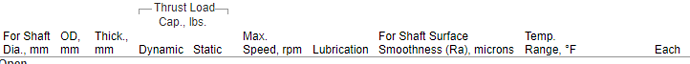

Next pic shows size of GC needle bearing washers. OD is ~38mm and there’s about 5mm of bearing surface.

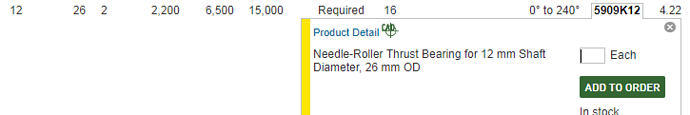

The below pic shows the big-ass Vorshlag bearing.

The below pic shows the underside of both camber plates and the top of the top hats. It shows how top hat and camber plate mates. Vorshlag on the left.

The below pic has everything inverted so you can see how the top hat mates with the spring. The Vorshlag design looks to me a little better here. I like how the camfered corner would help ensure the spring was able to easily pop back into place it it got unloaded.

The below pic shows the beefy steel top of the Vorshlag camber plate. Near as I could tell, there’s no AL in this camber plate at all, unlike like the slider in my mystery mfr camber plates. If you look closely at the above pic, you can seee that the steel plate that forms the base structure of the camber plate is a bit thicker in the Vorshlag design than in my camber plate. One can’t handle the Vorshlag camber plates w/o thinking that it’s a heavy fiercely strong design.

I like the big (gold) 22mm nut thing that threads on to the top of the strut. Easy to access. With my old camber plates I had to use a special socket that I had ground a bit to make it’s walls thin. Also lots of threads in the Vorshlag nut thing, which fixes a problem I’ve had with struts…not enough threads on the end of the strut engaged.