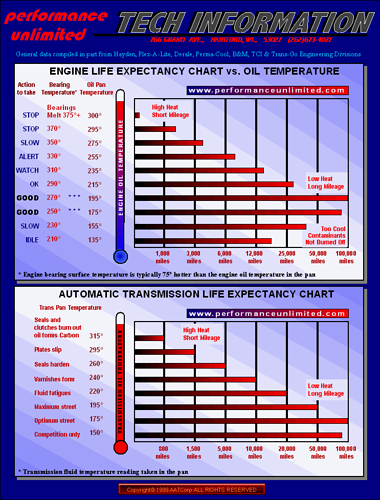

This is an interesting chart. It shows “how hot is too hot?” for both your engine oil and your tow vehicle’s transmission. It also shows how a pattern of short trips can mess up oil by not letting it get hot enough.

Transmission fluid for tow vehicle. For most modern cars, tranny and diff fluid are marketed as “lifetime fill”. Some years ago I bought a Ford F-150 with 112k miles on it. Previous owner was a petite girl that had put on lots of freeway miles. Truck looked brand new. Even the driver’s seat looked new, because she’d weighed so little.

I had an open trailer back then, so not much to pull. I was playing around with an Android App called Torque that would let you set up gauges fed by the OBD2 data stream. That app showed me that my tranny temps were surprisingly high. But I didn’t know what was normal for tranny temps. All I knew was that the tranny was supposed to be “lifetime fill”.

I had a shop replace the tranny fluid. Temp went from 235deg down to 190deg. Dang, what a huge difference. Imagine how much additional friction was going on inside of the transmission to generate such additional heat. According to the chart, the fluid change likely saved the transmission.