Jon was here this weekend and we swapped out the motor killed at RA last month. We put in a low mileage bottom end, with I-J scraper and a baffle, and a fresh head. We worked hard for 6hrs yesterday, thank god the garage has AC, and got it all done except for coolant and electrical. Then we went to a ballgame. No really. After not having a single bite to eat all day we walked a couple blocks to the stadium where the local minor league baseball team plays, and luxurated in beer and dogs.

Challenges and points of interest:

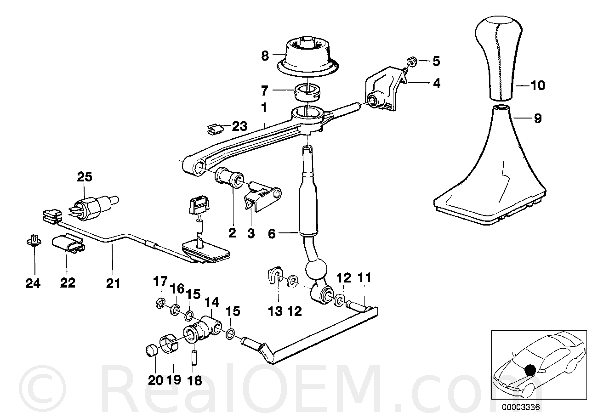

Jon’s car is missing the two little hooks that help hold the shifter carrier in at it’s rear anchor point. As a result the anchor point hands down a big and the driveshaft has been wearing away his shifter. We jury rigged something to hold the rear of the shifter carrier up a little higher but it probably won’t last.

The tranny slave cylinder was only being held on by one nut and it was ready to fall off. I can’t for the life of me imagine how the clutch worked with the slave almost off of the bellhousing and at a 45deg angle.

As usual I put the intake manifold on and then realized I’d forgotten the bitch tube, so that was a redo.

Jon’s clutch disk was worn to a mm’s thickness so we replaced both clutch disk and pressure plate. It was necessary to do that only once, and not 5x like my previous effort.

There were only 2 wires going to his starter solenoid. Odd.

My air compressor sucks.