We’ve not been doing much in the way of compliance inspections so far this year and I want to change that. So far tho, most of what I’ve been doing is running around the paddock trying to find that key video that will exonerate . But compliance inspections need to be done. For most of us, this will be our first time at Nationals. It would be pretty embarrassing to end up at odds with NASA National compliance inspectors come end of Aug. If that happens to you in Aug, and your cause is righteous I’ll help argue your side. But I’d rather fix things now by encouraging folks to, ah, not stray.

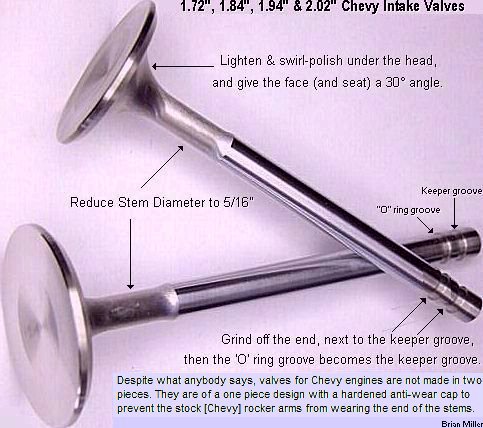

You may have heard rumors about this, but last month NASA compliance inspectors had some folks pull their intake manifolds and check intake ports and injectors. There was clear evidence of intake porting and valve under-cutting. We are not used to that level of compliance inspection in the SE. Personally, I hope we never get to that level of compliance inspection. But that gives you an idea of how serious NASA compliance inspectors are.

So I’ve been thinking how best to do compliance inspections. I’d much rather set everyone up for success then play gotcha and embarrass someone in front of their peers. With that in mind, here’s some things to think about before you pack your car up next week.

Things that are likely to be inspected at RA.

-Crank position sensor bracket.

-Flywheel check with magnet and the R. Patton profile tool. If you go ahead and drop your flywheel inspection plate now, you won’t have to hassle with it at the track.

-Thickness of engine mounts.