The O2 sensor doesn’t play in open loop (WOT). The way the O2 sensor could goof the mixture is by causing problems to LTFT (long term fuel trim). If the O2 sensor was reading rich, your DME would dial back the injectors. This would make you always lean.

Your DME goes to open loop when the TPS senses WOT, or when the AFM door fully opens (4000-4500rpm I think). At open loop it no longer listens to the O2 sensor, yet the LTFT fuel map adjustment still plays. Therefore the LTFT adjustment the DME learned at partial throttle is applied at full throttle.

Note what this learned LTFT means for swapping parts. If you power off the DME or replace an engine management part, you have to give the DME an opportunity to reset LTFT. This means some time at partial throttle, since learning doesn’t occur at open loop. How much time I’ve never been able to figure out, but I’d guess less than a minute or two.

I don’t think there’s a good test for how well the O2 sensor is working. Sure, you can test to see if it’s basically functional, but a CEL would probably tell you that. Testing to see if it’s working “well” would be a whole 'nother can of worms. As a narrowband device it’s oscillating between on and off based on AFR. A person would probably need an oscilloscope and a calibrated AFR source to ID how well the sensor was working.

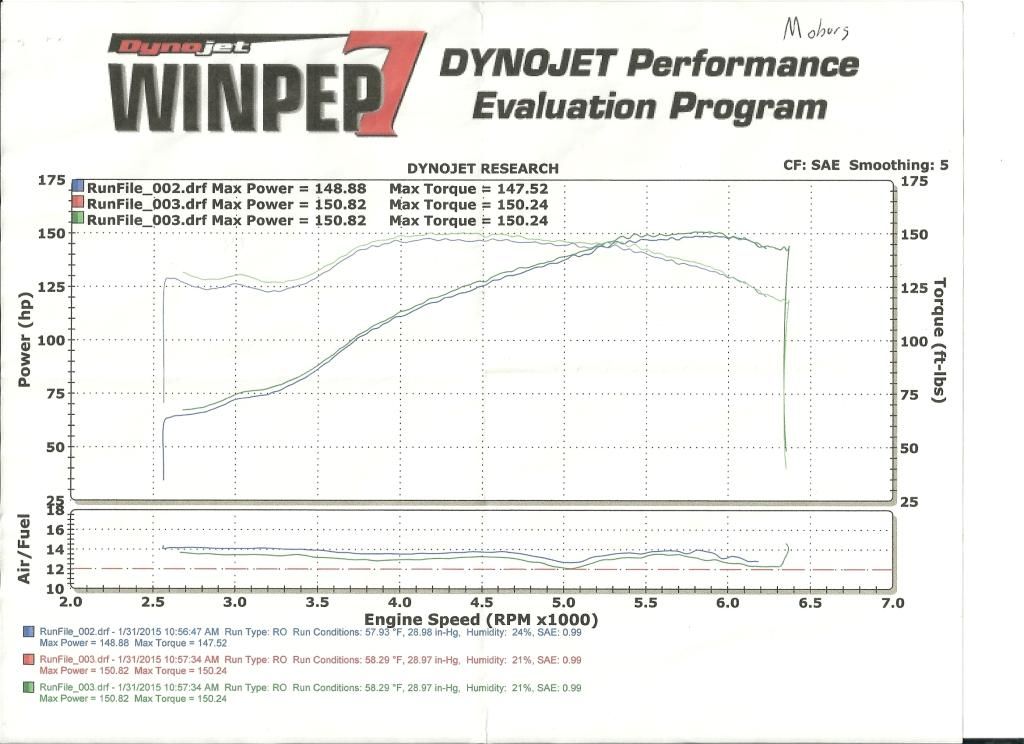

I have a F/A meter on my dash that is connected to my Traqmate. I installed it in '09(?) when I spent much of a season fighting engine management issues that I couldn’t seem to beat. The F/A meter told me I was running really lean. That would have fixed me up pretty quickly but, sigh, at the time I didn’t believe what it was telling me.

The other really handy gauge on the dash is fuel pressure. Eventually everyone experiences mysterious engine management issues. Having gauges like that on your dash gives you a baseline for normal behavior, and give you important clues when trouble strikes.

[/URL]

[/URL]