Hey everyone. My spec e30 project is happily back off the back burner, trying to get it running right now. Unfortunately since buying the car, it has had a pronounced single knock or tick, half engine speed, every rotation, regardless of rpm or cold vs warm.

First thing I did after bringing it home was adjust the valves, with no improvement. Recently rechecked them to find still in spec

.

In the last month I did a new timing belt and tensioner(needed belt and suspected bearing was bad), water pump, rotor, cam seal. Knock still there.

Leak down test yesturday (engine cold), suspecting a bent valve, showed 0.5%-1.5% on all cylinders.

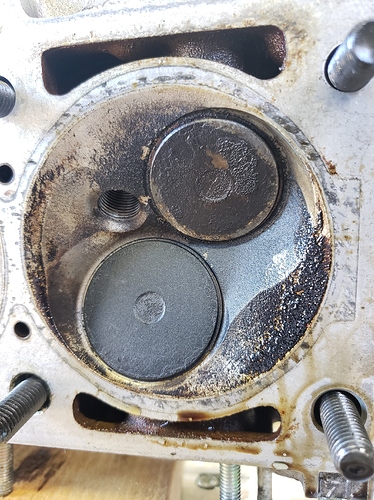

Ran the car today with no valve cover to hopefully catch something I missed or at least localize the sound but I’m still at a loss. Pushed on rockers, pulled plug wires one by one, was unable to change the knocking sound. I know it’s towards the front two cylinders. Is it still a bent valve closing slowly but sealing? Some kind of a worn rocker or cam bearing?