Sure, it behooves us to get off of the bumpstops, but we’ve spent the last 15yrs riding on them on likely every turn. I would argue that the most significant thing was the sudden realization that we were always too low, given that our springs were too weak to keep us off of the stops. Now we have stouter springs and adjustability to deal with it.

Bilstien Shock Discussion

Re: corner balancing. You know who else said that? Skeen–probably our fastest guy. I believe it. It’s not a huge deal to corner balance the cars now so I did it, but it’s not something I worry about every race.

There are some misunderstandings here. The idea that the new springs make us worse off for bump travel is just wrong.

I just pulled apart one of my front corners to take some pics. The bottom line is that the bump travel of the struts is slightly better, ride height being equal, and due to the new springs being so much stiffer, we are in a far better situation than we were for keeping off the bumpstops. I understand that there are some folks that disagree. I would encourage them to pull apart their stuff and take measurements.

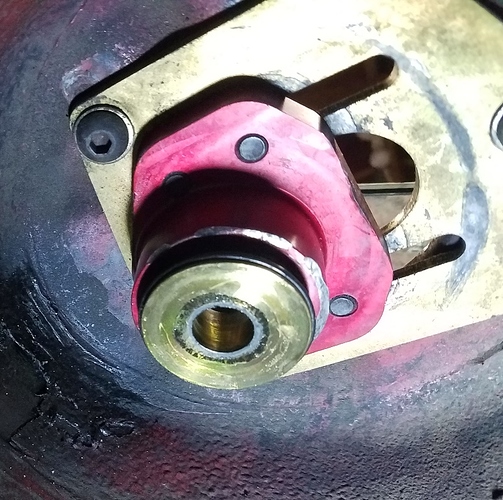

The first pic below shows the misalignment spacer shipped to GC camber plate owners. It is the piece that sets bump travel because it’s the piece that the strut shaft’s shoulders push up. All measurements of bumptravel and camber plates have to orient on the location in the camber plate that the strut shaft’s “shoulders” push on. That misalignment spacer sets the strut shaft “shoulders” 8mm below the lower surface of the camber plate.

The second pic is the cylindrical piece that used to be in the GC camber plate. It shoved down the old OEM spring hat, and also shoved down the shoulders of the strut shaft. Just like the misalighnment spacer, it’s 8mm. So the old GC solution shoved down our strut shaft 8mm + an additional 2mm thickness (yes, I measured it) of the OEM spring hat… Therefore the new location of the strut shaft gives us 2mm more bump travel then the old springs. Not less bump travel, more bump travel.

But here’s the big enchilada. The new front springs are 40-47% stiffer than the old springs, depending on who’s #'s for H&R Race you believe. Lets assume 40%. So 30mm of old bump travel would be the same as 42mm of bump travel now. So if your car is the same height as it used to be, due solely to the stouter springs, you are in a 40% better situation with the new springs.

The bottom line is that we are much better off than we were. This bump travel concern is simply new recognition of a 15yr old problem. Now we know that one of the reasons that our car was such a handful at 'the limit". We are now in a better situation because a) 40-47% stiffer front springs so the new springs require far less bump travel. b) The new springs bring adjustibility so we can lift the front a bit higher if we want, like the Aussies do, and c) our top hats are now compatible with conventional camber plates which will give us, I dunno, 15-20mm more bump travel if someone decides that “better” is not good enough.

Returning to this thread with new info, much of it contradicting what we (especially me) thought was true.

The other day Rich Bratton sent me a pic of the bumpstops inside of a Bilstein B8 strut insert. The bumpstops are ~3" of, I dunno, maybe polyurethane. The fact that the bumpstops are so tall is significant.

Lets assume that at full compression those 3" of bumpstops can squish down to 1". That’s jibes with my finding above when I attempted to fully compress a front corner and found 23mm of strut still above the gland nut.

Up above I ballparked our H&R spring available bump travel at 30mm. So imagine the insert’s bumpstops compressed from 3" to 1" at rest. 1" + 30mm is about 2 1/4". So at rest with H&R Race springs we already had our bump stops compressed by ~3/4". That would have had a huge impact on our effective spring rate. Because we didn’t just have 275lbs/in from the spring, we’d have had the sum of 275lbs/in + the spring rate of the bump stops squeezing down.

I did some poking around and it looks like 200lbs/in is a reasonable estimate for the spring rate of our B8 bumpstops. So our old front effective spring rate was ~515lbs/in (315+200) and our new front effective spring rate is ~725lbs/in (525+200).

Conclusions.

-

Our new front springs didn’t increase our effective front spring rate as much as we thought. 315 to 525lbs/in is a 67% increase. But when we take into account the bump stops the effective front spring rate increase was approx 515 to 725lbs/in. Only a 41% increase.

-

The fact that we never really get off of our bumpstops has to be beating the shit out of our front ends. We’ve certainly seen torn sheetmetal around the strut towers.

-

Eventually we’re banging out our polyeurethane bump stops and turning them into soup. So after a while the additional effective spring rate goes away, our front end gets softer, but then we REALLY bash the shit out of our strut towers when we bottom out. That fits anyone’s experiences?

-

There’d been lots of talk about how much more fun the new springs are on fast sweepers, and how they make the slow guys (like me faster) and therefore tighten up groups. This is particularly evident at Roebling Road where midpackers are 1sec faster and back packers 2secs faster. But now that we understand(?) the bump travel limitation of the B8, some other advantages come to the fore.

a) You can raise your front up a bit and gain some bump travel. So it’s not “woohoo, I have stiffer springs.” It’s "woohoo, I finally have the height adjustibility that gets it off of the damned front bumpstops.

b) The narrow spring and no tophat creates a more level camber playing field. Because of tweaked frames, some people used to be able to get a lot more camber than others and that’s not fair.

Just for clarity, the problem is not that the B8 is a shitty strut insert. The problem is that the B8 is tall. It has to be because it’s designed for the relatively tall OEM strut housing, which was designed for OEM ride height. We’ve lowered our cars so the height of the strut housing causes bump travel issues. Had Carter, years ago, wanted to spec a more appropriate height strut insert, he would have had to tell everyone to either shorten your strut housings or buy aftermarket housings. Both of those ideas add cost, so it’s easy to understand why he’d be wary of that route.

I talked to James Clay today about this. His take is that we should quit being so hesitant to raise the front of our cars a bit.

Can I squeeze anymore James Clay info out of you lol? Is it just an issue with the front or does the whole car need to be raised? Rack? If whole car needs to be at a higher height?

The discussion with James was about our lack of bump travel due to OEM strut housings and various solutions…one of which being cutting our struts and going to a shorter strut insert. The charm of raising the car’s front end is that it’s free. James’ point was that the idea that “lower is always better” is wrong. Suspension is complicated and there’s lots of variables. But there is one thing that we can most certainly depend on…of the various solutions to our lack of bump travel, raising the front of the car is the cheapest solution.

The discussion wasn’t about the rear nor about the rack.

Im assuminh trimming bumpstops is against the rules. Although, I dont see why its not something to look into as it doesnt effect the valving.

Back when I started with the old springs, I pointed out that there is an advantage to trim the bump stop. Even H&R sends you a document with the springs explaining to trim the bump stop. Now with the new spring setup, the top plate stack up counteracts the bump stop. Where I would be worried now to bottom out the wheel inside the fender before bottoming the bump stop.

Yes, trimming bumpstops is against the rules. The rules are designed to limit cost. Every additional mod the rules allow adds cost. Or adds hassle if you do your own work.

The top plate “counteracts” the bump stop?

Bottoming out the wheel inside the fender? The new springs aren’t an opportunity to lower the front of your car. The springs effort helped us realize that we’ve been driving on our bumpstops all these years. The springs allow us to raise our front ends and get some suspension travel back. Sure, there’s going to be some hardheads that instead lower their cars. . Freedom includes the freedom to pursue bad ideas.

I raised my front end ~20mm.

New setup has less top plate stack up. For the same ride height, the shock can travel more before bottoming out.

With that said, in the past, on my other car, I have ran into the issue where my wheel would touch the inside of the fender/whitebody/frame. Basicly, the bump stop was not preventing my wheel from traveling too far, causing weird wheel lockups.

About raising the front end. We can have much better roll centers now! Still studying and would need to take some actual dimensions, but there are basic actions that make good amounts of difference. Biggest advantage is the diameter of our spring.

Just to bring a dead thread back. I bought a car again and noticed it had this “spring upgrade.”

I was surprised that the setup didn’t include a change to shocks. When the vehicle is at full droop I can take the rear spring out. It’s just barely touching the upper perch cone to keep it from falling out on its own. There’s nothing holding it in. I honestly can’t remember if this was a concern at all with the old H&R springs. Even the front spring has a 2" gap at droop. While I’m not so worried about the front, the rear is scary.

Can we at least add travel limiters with straps? Seems like a safety issue. Straps are probably $50 and would at least band aid the issue for a little while.

My car has been on a lift now for a week. At full droop the rear springs are still high enough that the tip of the white plastic cone is inserted a bit, prob .5" into the top of the spring coil. My rear springs are pretty much bottomed out right now so the adjuster isn’t pushing them up anything unusual.

There is discussion elsewhere re. putting in a heavy washer below the springs to reinforce the trailing arm spring perch. Those washers are really thick so that would mitigate your issue a bit. Odd that you’ve got so much spring droop. Post a pic maybe?

Scott,

Forgive my lack of depth of knowledge, but wouldn’t a helper spring “help” this issue? Seems like this spring looseness at full droop was brought up a couple of years ago on FB after some folks starting actually installing these kits, and I don’t remember much about the resulting discussion, and of course can’t look it up on FB.

Something like this, but of course for the SpecE30. Morehead Speed Works Hyperco Helper Spring Set

That’s a very interesting idea. I’d never even heard of the things. You’re MidS region, correct? I’d suggest you write up that idea and send it to Brian as a formal request for a rule change. Talk to him about being allowed to install them on your car for testing. No way they’d get approved without testing.